Customized Centrifugal Blower

100000 INR/Unit

Product Details:

- Speed 2800 RPM

- Revolution 2800 RPM

- Noise Level <80 dB

- Power Consumption 3.7 kW

- Voltage 220-440 V

- Power 5 HP

- Pressure Upto 150 mm WG

- Click to View more

X

Customized Centrifugal Blower Price And Quantity

- 100000 INR/Unit

- 1 Unit

Customized Centrifugal Blower Product Specifications

- Centrifugal Fan

- Electric

- Round

- Up to 5000 CFM

- Upto 150 mm WG

- 5 HP

- Mild Steel

- 2800 RPM

- 2800 RPM

- Floor Mounted

- 3.7 kW

- <80 dB

- Customized Centrifugal Blower

- 220-440 V

Customized Centrifugal Blower Trade Information

- 2 Unit Per Month

- 10-20 Days

Product Description

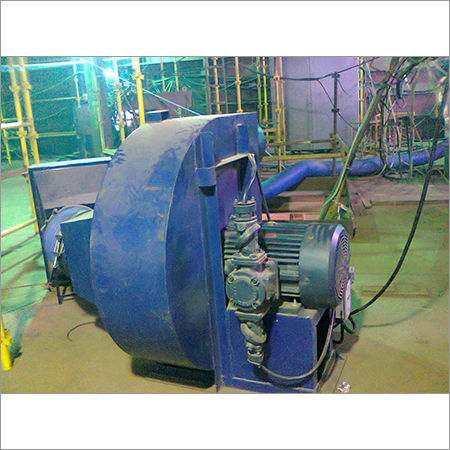

Backed by rich industry experiences, we are highly engaged in manufacturing and supplying an optimum quality range of Customized Centrifugal Blower. Offered range of blowers is highly useful for industries like biotech, chemical, and pharmaceutical for different applications. Engineered and developed with extreme care, this product is reckoned for consistent performance and robust structure. This Customized Centrifugal Blower is available in different specifications as to meet the requirement of our clients.

Features:

- Rugged construction

- Less maintenance

- Corrosion resistance

High Efficiency and Durability

This centrifugal blower is designed with a backward curved impeller and mild steel construction, maximizing efficiency and durability. The direct drive system reduces maintenance needs, while the IP55 motor protection safeguards against dust and moisture, extending operational lifespan in industrial settings.

Optimal Performance for Industrial Applications

Suited for ventilation, dust collection, and industrial exhaust, this blower delivers up to 5000 CFM of air volume and operates at 2800 RPM. The base plate mounting and floor installation ensure stability, while its blue, painted finish protects against corrosion and wear, supporting consistent performance.

FAQs of Customized Centrifugal Blower:

Q: How is the customized centrifugal blower typically installed?

A: The centrifugal blower is floor mounted on a base plate, ensuring secure and stable positioning. This installation method is suitable for most industrial environments and allows for straightforward integration into ventilation or dust collection systems.Q: What is the maximum air volume and pressure that the blower can handle?

A: This blower delivers an air volume of up to 5000 CFM and can generate a pressure of up to 150 mm WG, making it suitable for robust industrial ventilation and dust collection demands.Q: When should I use this centrifugal blower in my facility?

A: Use this blower when you require reliable airflow for ventilation, dust collection, or exhaust applications in temperatures up to 80C. It is an ideal solution for maintaining air quality in industrial settings requiring consistent and powerful air movement.Q: Where can the centrifugal blower be applied?

A: It is commonly used in factories, workshops, manufacturing plants, and industrial premises across India for applications like air extraction, dust collection, and large-scale ventilation.Q: What benefits does the backward curved impeller provide?

A: A backward curved impeller enhances efficiency by minimizing energy losses and ensuring steady airflow. It operates quietly (under 80 dB) and is less prone to clogging, contributing to lower maintenance and operational costs.Q: How does the blower ensure protection and durability in industrial environments?

A: The blower is constructed from mild steel, features durable painted finishing, and provides IP55-rated motor protection. These elements ensure resilience against harsh conditions, including dust, moisture, and mechanical impact, ensuring longevity.Q: What is the process for maintaining this centrifugal blower?

A: Regular inspection includes checking the impeller, motor, and housing for dust accumulation or wear. Since it uses a direct drive, maintenance is minimal, requiring primarily cleaning and periodic lubrication as recommended in the product manual.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Centrifugal Blower' category

|

SALES - TECH ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |