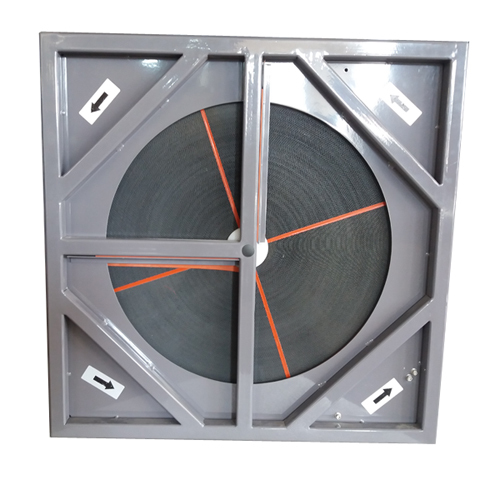

Desiccant Rotor

Product Details:

- Type Desiccant Rotor

- Material Silica Gel/Aluminium Alloy

- Capacity Up to 4500 CFM

- Power 2.2 kW

- Voltage 220/380 V

- Technology Honeycomb Rotor Technology

- Coverage Area Up to 5000 sq.ft.

- Click to View more

Desiccant Rotor Price And Quantity

- 100000 INR/Unit

- 1 Unit

Desiccant Rotor Product Specifications

- No

- LED Display

- Honeycomb Rotor Technology

- -20C to 60C

- Up to 4500 CFM

- Desiccant Rotor

- Microprocessor Based

- Up to 70

- 2.2 kW

- 800 mm x 600 mm x 900 mm

- Silica Gel/Aluminium Alloy

- 220/380 V

- 1350 RPM

- 65 kg

- Up to 5000 sq.ft.

- Yes, Integrated

- Silver/Grey

Desiccant Rotor Trade Information

- 2 Unit Per Month

- 10-20 Days

Product Description

This 304 grade stainless steel made Desiccant Rotor is accessible in 23.5 kg weight. Developed as per CE specifications, this equipment is used for industrial air drying purpose. Excellent moisture adsorption performance and advanced mechanism are its main features. Provided Desiccant Rotor is acknowledged for their high temperature proof design, good water resistant attributes, weather protection capacity, unique surface hardness and odor free design. This system can be cleaned easily by applying organic solvents and water. Split type structure of this system can be assembled easily. This rotor comprises of bearings, spoke etc. Long working life is one of its key aspects.

Desiccant Rotor Technical specification

| Material Grade | 304SS |

| Weight | 23.5 Kgs |

| Material | Stainless Steel |

| Warranty | 1 Year |

| Pack Type | Carton Box |

Unmatched Moisture Control with Advanced Technology

Utilizing silica gel and aluminium alloy construction, the Desiccant Rotor leverages honeycomb rotor technology to deliver consistent humidity control over a wide temperature range (-20C to 60C). Its microprocessor-based controls and integrated sensors ensure precise, reliable operation, making it suitable for diverse environments and industries.

Robust Safety and Longevity Features

Safety is prioritized with EN 13501 fire resistance compliance and a noise level maintained below 60 dB for operator comfort. The pre-installed G4 filters extend rotor life, while the easy-access panels enable straightforward maintenance, supporting up to 8 years of rotor operation to minimize downtime and replacements.

FAQs of Desiccant Rotor:

Q: How is the Desiccant Rotor installed and what mounting options are available?

A: The Desiccant Rotor can be installed either on the floor or mounted on a wall to suit different site requirements. Its compact dimensions and accessible panels make the installation process straightforward for both new and existing facilities.Q: What maintenance process is involved for the Desiccant Rotor?

A: Maintenance is simplified thanks to easy-access panels and pre-fitted G4 filters. Regular filter checks and scheduled inspections help maintain optimal performance, and the rotor itself is designed to last up to 8 years under typical usage.Q: When should the Desiccant Rotor be used for optimal benefits?

A: The unit is ideal for use in industrial and commercial spaces where precise humidity control is critical, such as pharmaceutical plants, data centers, and warehouses, especially in extremes of temperature (from -20C up to 70C operating conditions).Q: Where can the Desiccant Rotor be deployed effectively?

A: This system is suitable for large spaces up to 5,000 square feet, and is commonly installed in factories, storage areas, laboratories, and other environments across India that require reliable moisture management.Q: What technology does the Desiccant Rotor employ for humidity control?

A: It uses a honeycomb rotor technology constructed from silica gel and aluminium alloy. The integrated microprocessor-based control system and humidity sensor automatically regulate moisture levels for consistent dehumidification.Q: What are the key benefits of choosing this Desiccant Rotor?

A: Benefits include high dehumidification efficiency (>90%), robust fire resistance, minimal noise, easy maintenance, long rotor lifespan, and energy savings with microprocessor controls. Flexible installation and wide coverage further enhance its utility.Q: How does the regeneration and airflow process work in this device?

A: The standard regeneration airflow is 180 m/h, which reactivates the desiccant material using a controlled stream of air. This process ensures that the rotor always provides effective moisture removal and consistent performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

SALES - TECH ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |